Quality Inspector

How it Works

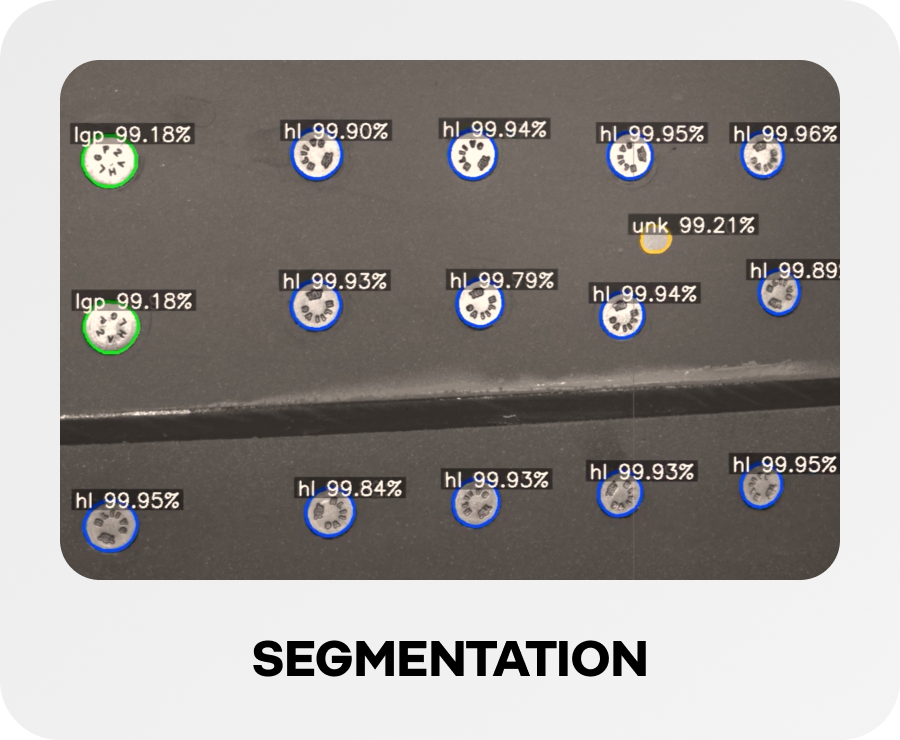

Quality control in manufacturing varies from one production process to the other. That is why Quality Inspector is not a one-size-fits-all product. Instead, we have collected pre-trained models for many different scenarios, which we update regularly. Quality Inspector is a framework that enables us to take these models and quickly tailor them to your needs.

Hardware Compatibility

Quality Inspector can be deployed using regular 2D cameras, as well as on smartphones, thermo cameras, 3D cameras and many more. The data can be processed both in cloud and on our/yours Edge devices.

Could Quality Inspector boost your business? Request a free demo!

About the Demo

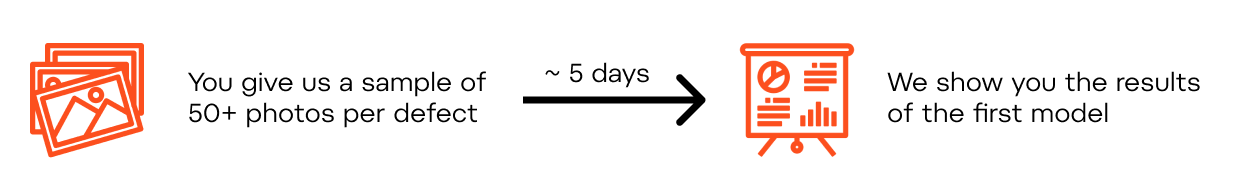

The free demo demonstrates that quality inspection can be performed using computer vision and what level of accuracy can be achieved even with low-quality photos and a low number of samples. Quality Inspector then enables us to take these first models and train them for high performance and in a way that makes them easy to productionalise.

We can give you a high-performance model based on the current state-of-the-art technology. On top of that, we can also monitor its performance, including reporting back to you and an easy way to retrain when new data comes or the factory floor changes.

Search

Search